Additive manufacturing of polymer-derived ceramics

- ISNM

- Mar 18, 2016

- 1 min read

BY ZAK C. ECKEL, CHAOYIN ZHOU, JOHN H. MARTIN, ALAN J. JACOBSEN, WILLIAM B. CARTER, TOBIAS A. SCHAEDLER

SCIENCE01 JAN 2016 : 58-62

http://science.sciencemag.org/content/351/6268/58

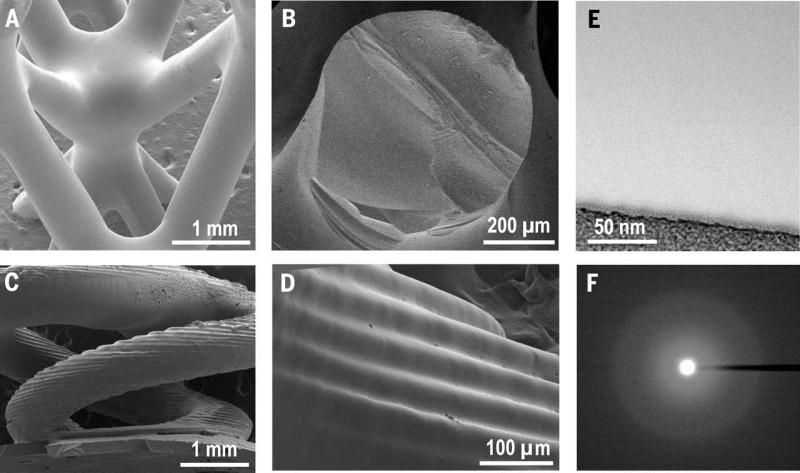

Preceramic monomers can be patterned, using stereolithography or 3D printing, into complex shapes and cellular architectures.

Abstract

The extremely high melting point of many ceramics adds challenges to additive manufacturing as compared with metals and polymers. Because ceramics cannot be cast or machined easily, three-dimensional (3D) printing enables a big leap in geometrical flexibility. We report preceramic monomers that are cured with ultraviolet light in a stereolithography 3D printer or through a patterned mask, forming 3D polymer structures that can have complex shape and cellular architecture. These polymer structures can be pyrolyzed to a ceramic with uniform shrinkage and virtually no porosity. Silicon oxycarbide microlattice and honeycomb cellular materials fabricated with this approach exhibit higher strength than ceramic foams of similar density. Additive manufacturing of such materials is of interest for propulsion components, thermal protection systems, porous burners, microelectromechanical systems, and electronic device packaging.

Bình luận